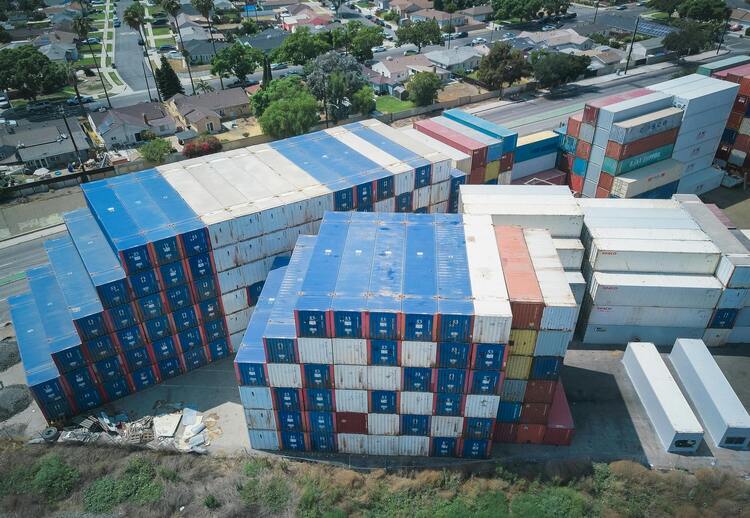

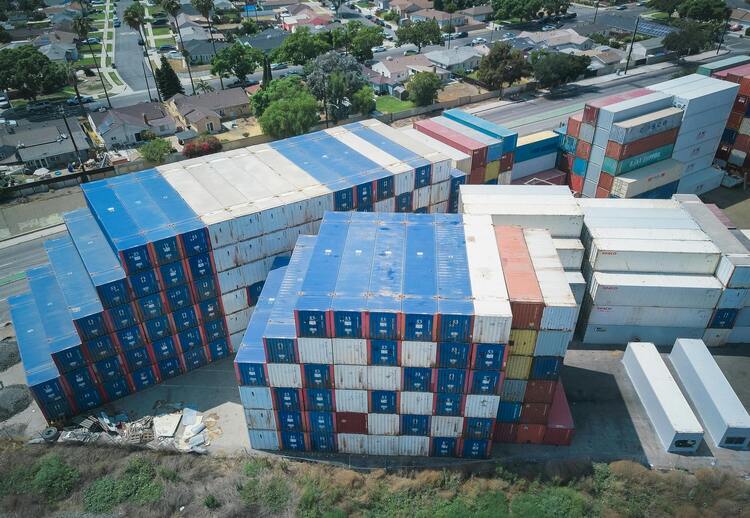

Warehouse and Distribution Solutions for Optimized Supply Chain Management

Distribution is the process of delivering goods from the warehouse to the final customer or retail location. Efficient distribution ensures that products are delivered on time, minimizing delays and keeping customers satisfied. Here are some key benefits of optimizing distribution in your supply chain:

- Improved Customer Satisfaction: Fast and accurate deliveries enhance customer experience and loyalty.

- Reduced Shipping Costs: By optimizing shipping routes and consolidating shipments, businesses can lower transportation costs.

- Increased Flexibility: Efficient distribution solutions allow businesses to quickly adapt to changing market demands or unexpected surges in orders.

Key Benefits of Professional Warehousing Services

1. Cost Reduction

Professional warehousing solutions help reduce overhead costs by optimizing space, minimizing waste, and preventing stockouts. Centralized warehousing also allows businesses to take advantage of economies of scale.

2. Scalability

As your business grows, warehousing solutions can be scaled to meet increasing demands. This allows for flexibility in managing larger volumes of goods and ensures that the supply chain runs smoothly during peak seasons.

3. Enhanced Inventory Accuracy

Warehousing solutions that include automated inventory management systems significantly reduce human error and improve the accuracy of stock counts, reducing the risk of overstocking or understocking.

4. Faster Order Fulfillment

Warehouses equipped with advanced fulfillment systems, such as pick-and-pack services, ensure faster and more accurate order processing, leading to quicker delivery times and happier customers.

How to Choose the Right Warehouse Partner

Selecting the right warehouse partner is essential for optimizing your supply chain. Here are some factors to consider:

- Location: Choose a warehouse located near your primary customer base or major shipping routes to reduce transit times and shipping costs.

- Technology: Ensure the warehouse uses advanced technologies like automated systems and real-time tracking to streamline operations.

- Capacity: Select a warehouse with the flexibility to scale as your business grows, ensuring it can handle increased volume during peak seasons.

- Security: Opt for warehouses that offer robust security measures, including video surveillance, access control, and insurance.

Conclusion: Optimizing Your Supply Chain with the Right Warehousing Solutions

Professional warehousing and distribution services play a key role in optimizing your supply chain. From cross-docking and transloading to pick-and-pack fulfillment and inventory management, the right solutions can reduce costs, improve customer satisfaction, and enhance efficiency.

Ready to optimize your supply chain with professional warehousing solutions? Contact us today to learn more about how we can help streamline your logistics and enhance your business operations.